Theko ea fektheri 1050 3003 Aluminium Plate Prices

Mokhoa oa ho sebetsa oa mochini o ts'oarellang oa fiber laser o ts'oaretsoeng ka letsoho, oa ho ts'oara ka letsoho oa tenyetseha ebile o bonolo, 'me sebaka sa ho tjheseletsa se telele. Ho sebelisa letsoho tjheseletsa sethunya ho nka sebaka se fetileng e tsitsitseng leseli tsela e na le melemo ea ho tshebetso e bonolo, seams e ntle tjheseletsa, lebelo tjheseletsa ka potlako 'me ha ho consumables.For tjheseletsa tšesaane lipoleiti tšepe e sa hloekang, lipoleiti tšepe, lipoleiti galvanized le lisebelisoa tse ling tsa tšepe, ho ka ho phethahetseng nka sebaka sa setso argon arc tjheseletsa, tjheseletsa motlakase le mekhoa e meng. Mochini o ts'oaretsoeng ka letsoho oa faeba laser tjheseletsa o sebelisoa haholo bakeng sa welding ea laser ea sebaka se selelele le li-workpieces tse kholo.

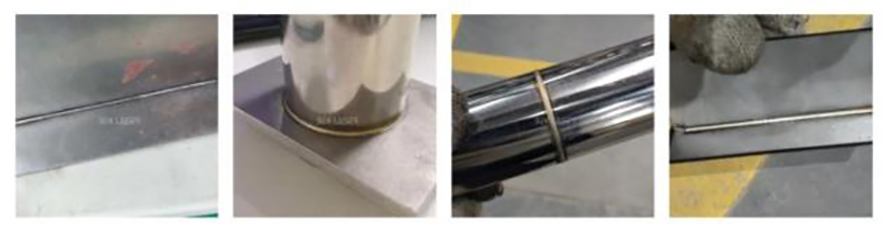

Sebaka se amehileng ke mocheso se senyenyane nakong ea welding, 'me se ke ke sa baka deformation ea mosebetsi, blackening, le mesaletsa ka morao. Botebo ba ho tjheseletsa bo boholo, ho tjheseletsa ho tiile, mme ho qhibidiha ho lekane. Handheld Fiber laser welding machine is a laser welding equipment that couples the high energy laser beams into the optical fiber, ka mor'a phetiso ea sebaka se selelele, ebe e fetoloa mabone a tšoanang ka seipone se kopanyang hore se tsepamiselitsoe ho sebetsa. Mekhoa ea ho tjheseletsa e kenyelletsa welding e otlolohileng, welding ea paraller, stitch welding joalo-joalo.

Likaroloana

1. Fast tjheseletsa lebelo, 2 ~ 10 makhetlo a ka potlako ho feta setso tjheseletsa.

2. Sekhahla sa weld se tšesaane, botebo ba ho kenella bo boholo, taper e nyenyane, e nepahetseng e phahame, ponahalo e boreleli, e bataletse ebile e ntle.

3. Palo ea deformation ea mocheso e nyenyane, 'me sebaka se qhibilihisang le sebaka se amehileng ke mocheso se moqotetsane ebile se tebile.

4. Sekhahla se phahameng sa ho pholisa, se ka etsang weld sebopeho se setle sa weld le ts'ebetso e ntle ea manonyeletso.

5. Laser welding e na le lisebelisoa tse fokolang le bophelo bo bolelele ba tšebeletso.

6. Ho sebetsa ha bonolo ha ho hloke koetliso, ho boloka tikoloho.

Kopo

Laser tjheseletsa ka sebelisoa ka tjheseletsa tšepe e sa jeleng paate, aluminium, koporo, chromium, nickel, titanium le tšepe tse ling kapa metsoako, ka boela sebelisoa bakeng sa mefuta e fapaneng ya tjheseletsa pakeng tsa thepa e fapaneng, tse kang: koporo - koporo, titanium - khauta, Titanium - molybdenum, nickel - koporo le joalo-joalo.

Mekhahlelo

| Mohlala | BEC-HW1000 |

| Laser Wavelength | 1080 nm± 5 |

| Mofuta oa Laser | Tšusumetso e tsoelang pele |

Mehlala

Pontšo ea Sehlahisoa